Mobile Instrument has been providing NIST traceable calibration and repair services on a wide array of test and measurement instruments since 1959. Our commitment to excellence has allowed us to be able offer honest and prompt solutions to meet our customers’ business requirements and increase their productivity. We constantly update and expand our calibration capabilities in an effort to fully meet the requirements of our customers. The full range of our services includes:

Calibration Services That We Provide:

In-Lab Calibration

The majority of our calibration are done at our laboratory facility. Our friendly staff would be happy to accommodate you through our front counter drop off or you can ship your instruments to our laboratory. We will quickly process your calibrations and notify you when they are ready for pickup or shipment back.

Onsite Calibration

We will bring our technicians and our standards to your location to provide calibration services at your facility. This scheduled service can eliminate instrument downtime and the need for spares and minimize interruptions to your manufacturing process.

Pick-up and Delivery Services

Mobile Instrument offers convenient pick-up and delivery service for local customers. After hours and weekend services are also available with advanced notice.

Comprehensive Calibration Services for Every Industry

At Mobile Instrument, our trusted calibration services and precision testing solutions support a wide range of industries across the Gulf Coast, including Pensacola, FL. Whether you rely on sensitive instruments in the field or in the lab, our accredited calibration lab ensures accuracy, compliance, and reliability for every application.

We proudly serve the following industries:

• Oil & Gas.

• Shipping.

• Aerospace.

• Manufacturing.

• Aviation.

• Power & Energy.

• Construction.

• Telecom.

• Maritime.

• Chemical.

• Engineering & Surveying.

From field calibration to comprehensive laboratory testing, we tailor our services to meet the unique needs of every industry we serve.

Accuracy and Reliability You Can Trust

With a strong focus on precision and performance, we ensure every instrument meets exacting professional and regulatory standards.

Here’s why clients continue to trust our expertise:

- NIST Traceable Standards: Every calibration follows strict NIST guidelines to guarantee precision and consistency.

- Highly Skilled Technicians: Our experienced team uses advanced testing equipment and proven methods for dependable outcomes.

- Reliable Documentation: Each service includes complete calibration certificates and traceability records for compliance and audits.

- Quality-Controlled Environment: Our lab conditions are tightly managed to ensure repeatable, high-accuracy results.

- Proven Industry Experience:

With decades of service since 1959, we’ve built a reputation for excellence and reliability.

For precise, trustworthy calibration results, contact Mobile Instrument today at (251) 660-7474 to schedule your equipment calibration service.

Reliable Calibration Services That Keep Your Equipment Accurate and Compliant

Accurate measurements protect your operations, your safety standards, and your bottom line. Mobile Instrument delivers dependable calibration services designed to reduce downtime, improve consistency, and support regulatory compliance across critical industries. Whether your team relies on routine testing or precision diagnostics, our technicians bring accuracy directly to you through efficient on-site calibration and detailed documentation. Call us at (251) 660-7474 today to schedule professional support and keep your instruments performing at their best.

FAQs About Calibration Services, On-Site Calibration, and Instrument Calibration

What Are Calibration Services and Why Are They Essential for Equipment Accuracy?

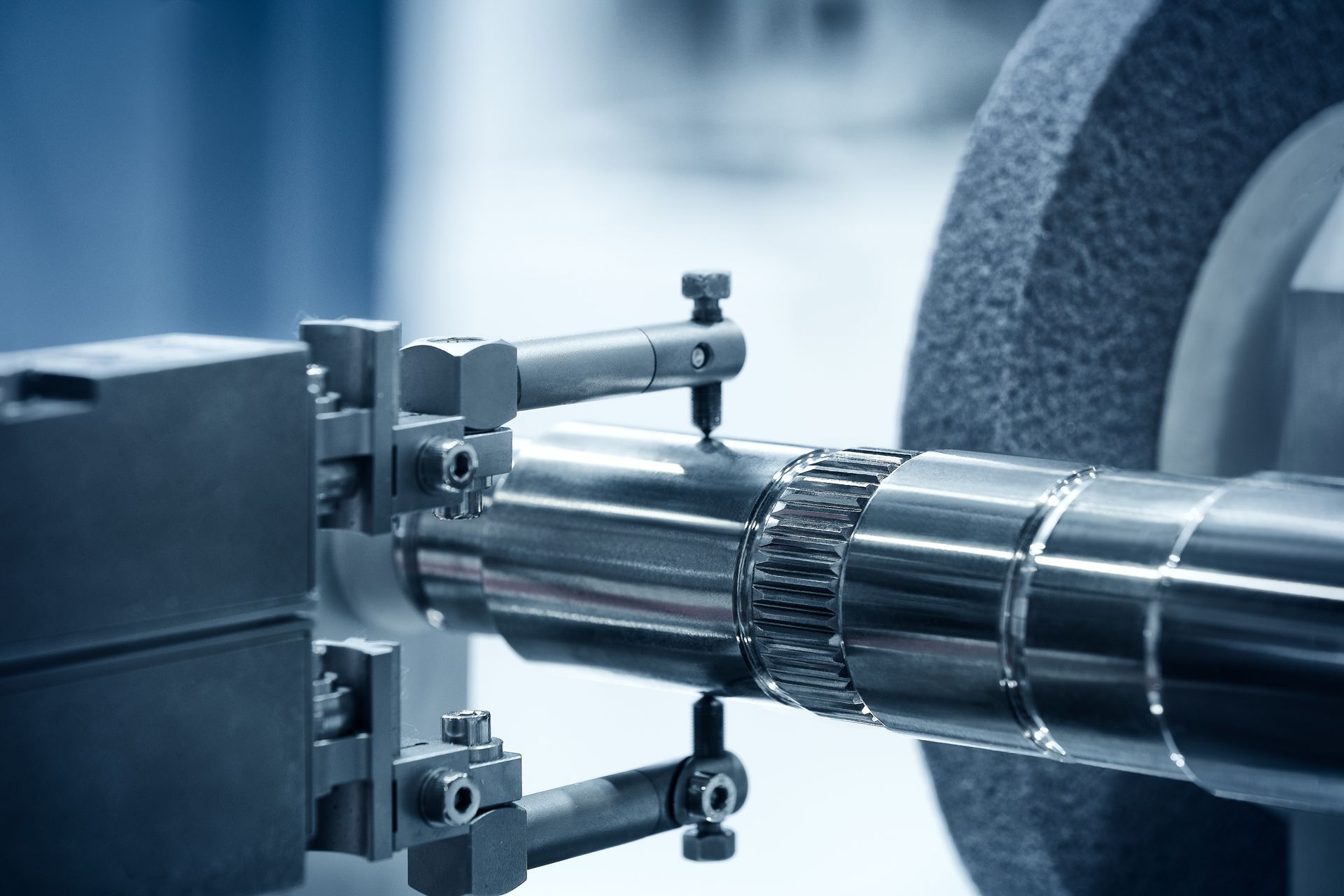

Calibration services ensure that measurement instruments provide accurate and repeatable results by comparing them against known standards. Over time, through everyday use, environmental conditions, and handling, instruments can drift out of tolerance. Regular calibration minimizes errors, protects product quality, and helps organizations meet compliance requirements. Consistent instrument calibration also reduces rework, safety risks, and costly operational mistakes.

How Does On-Site Calibration Benefit My Operations Compared to Off-Site Service?

On-site calibration allows your equipment to be tested and adjusted at your facility, eliminating shipping delays and reducing operational downtime. This approach keeps instruments in their typical operating environment, improving accuracy and reliability. By choosing on-site support, businesses gain faster turnaround times, improved scheduling flexibility, and uninterrupted workflows while still receiving high-quality calibration services.

What Types of Instruments Can Be Included in Instrument Calibration Programs?

Instrument calibration programs can cover a wide range of measurement tools, including pressure gauges, temperature sensors, electrical meters, torque tools, and dimensional equipment. A structured calibration schedule ensures each instrument is serviced in line with its usage and criticality. Comprehensive calibration services help organizations maintain consistent performance across all devices while reducing the risk of inaccurate readings.

How Often Should Calibration Services Be Performed on Critical Instruments?

The frequency of calibration services depends on several factors, including manufacturer recommendations, usage intensity, regulatory requirements, and environmental conditions. High-use or safety-critical instruments typically require more frequent checks. Establishing a regular instrument calibration interval helps detect drift early, maintain compliance, and ensure that measurements remain dependable throughout daily operations.

Can On-Site Calibration Reduce Equipment Downtime and Production Delays?

Yes, on-site calibration is specifically designed to minimize downtime by servicing instruments without removing them from your facility. Technicians work around operational schedules to maintain productivity while ensuring precision. This approach streamlines maintenance planning, supports faster corrective actions, and ensures calibration services are completed with minimal disruption to daily operations.

Why Is Instrument Calibration Important for Safety and Compliance?

Accurate instrument calibration directly impacts safety, product integrity, and regulatory adherence. Out-of-tolerance instruments can lead to incorrect decisions, failed inspections, or hazardous conditions. Routine calibration services help mitigate these risks by ensuring every measurement meets required standards and operational expectations.

How Do Calibration Services Support Long-Term Cost Savings?

Investing in regular calibration services reduces costly errors, extends equipment life, and prevents unexpected failures. Accurate instruments improve efficiency, lower scrap rates, and reduce rework. Over time, consistent instrument calibration lowers maintenance costs and helps organizations operate more predictably and profitably.

Schedule Professional Calibration Support Today

When accuracy matters, trust Mobile Instrument for dependable on-site calibration, precise instrument calibration, and consistent calibration services that support your operational goals. Our experienced technicians help protect your equipment performance, compliance, and productivity near Gulfport MS. Call us at (251) 660-7474 today to schedule service and ensure your instruments remain accurate, reliable, and ready for use. Contact us now to learn more.